Product lines

We work with different product lines in order to offer an optimal quality service to our customers

Technological advances in Machine Vision have their application in the industrial sector. The combination of vision cameras and laser technology with industrial robots supports multiple applications for industry and services in general.

At PROINGESA we develop complex Industrial Machine Vision systems that allow product inspection, contactless presence control, character reading or component identification. This maximises efficiency in production and guarantees the quality of the final product.

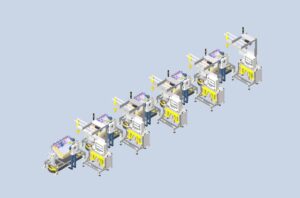

Automation offers flexible solutions for industrial production. Our accumulated experience in automation and robotisation allows us to design and manufacture advanced systems to provide solutions to our customers' needs.

PROINGESA is a key partner in this field as we are dedicated to the design, manufacture and commissioning of transport systems in logistics processes, with overhead conveyors, floor conveyors and robotised with AGV mobile platform.

Advanced production systems require the use of flexible lines and robots are the components par excellence to optimise productivity. At PROINGESA we implement. customised robotic cells for handling operations, welding, deburring, silicone application, riveting, even with laser guidance and artificial vision.

The industrial needs of our customers are diverse and rigorous in terms of requirements, which is why the technological support must be optimal. Specialised machinery tailored to the customer's needs is one of the pillars of our activity. At PROINGESA we design, manufacture and start up machines for multiple screwing, sealing, laser marking, vehicle assembly, or any other customer requirement.

At PROINGESA we are ready to lead a significant advance in the application of new technologies to robotised transport with AGVs for multi-sector applications.

Thus, we offer innovative mobile robotics solutions for industry, services and hospitals,, where we apply various navigation technologies to adapt to the needs of each customer:

- Magnetic guidance navigation

- Opto-guided navigation

- Free rotating laser navigation

- Free navigation through contour maps

Our expertise in the design and manufacture of specific machinery is also focused on customers in need of peripheral machines for the automotive plastics industry. We manufacture special machinery for plastics processing, such as bumper punching, fuel tank machining, hot plate and ultrasonic welding of plastics, as well as assembly stations...

Our innovative turnkey lines offer a comprehensive solution for the efficient manufacturing of various components such as battery assembly, fuel cells, electronic modules, etc. ensuring quality production and an efficient process.